What is the purpose of the Pre Trip Inspection Checklist form?

The Pre Trip Inspection Checklist form is designed to ensure that a vehicle is safe and ready for operation before starting a trip. By completing this checklist, drivers can identify any potential issues that may compromise safety and address them before hitting the road.

Who is responsible for completing the Pre Trip Inspection Checklist?

The driver of the vehicle is responsible for completing the Pre Trip Inspection Checklist. This accountability ensures that the person operating the vehicle is aware of its condition and can take the necessary steps to ensure safety during the trip.

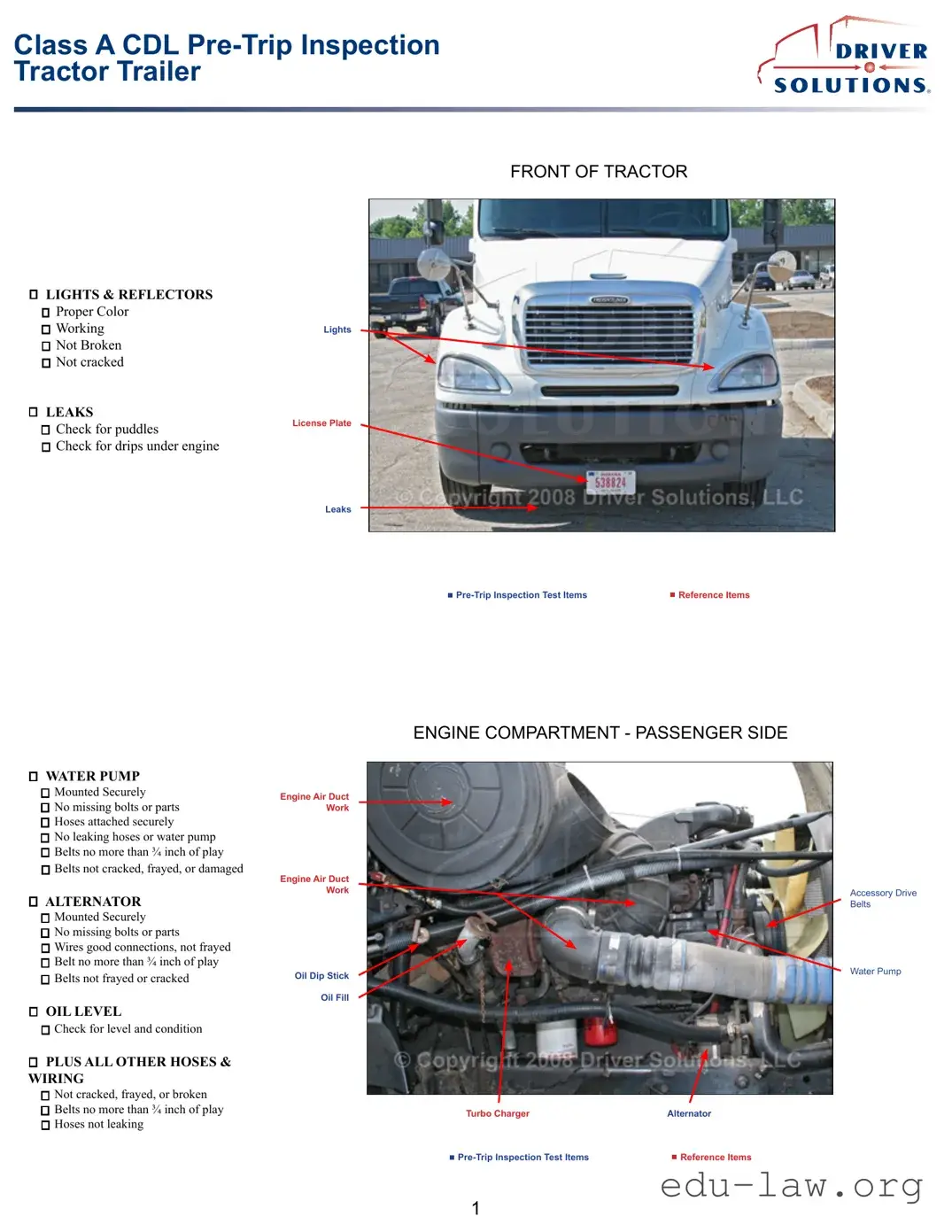

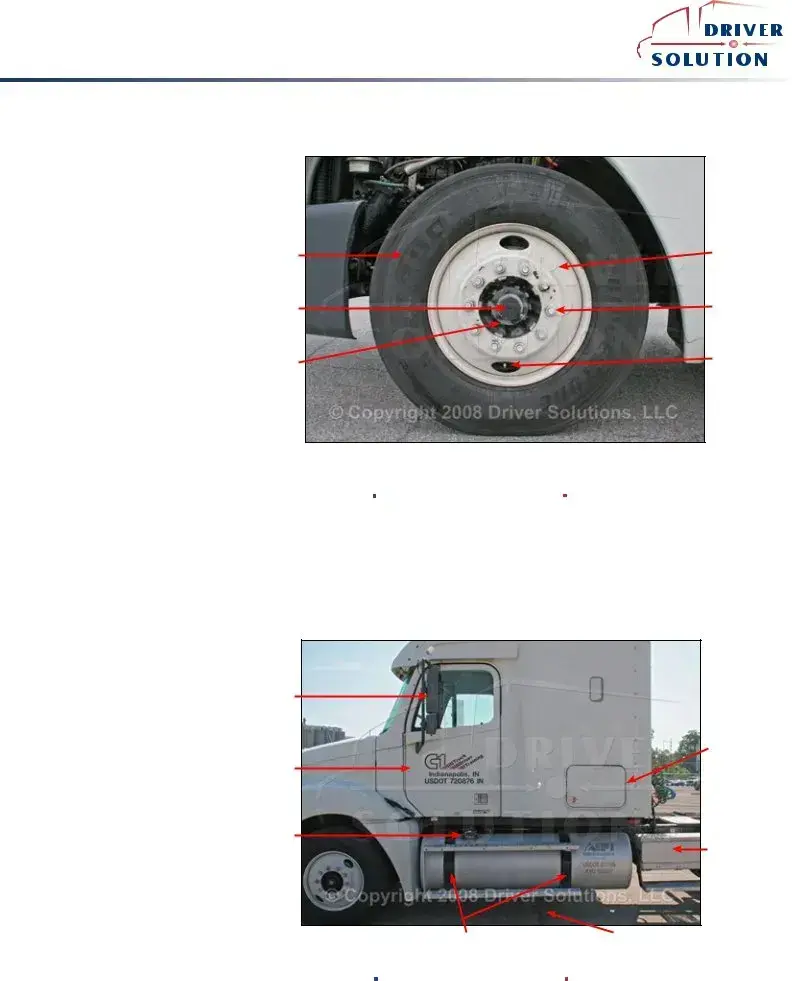

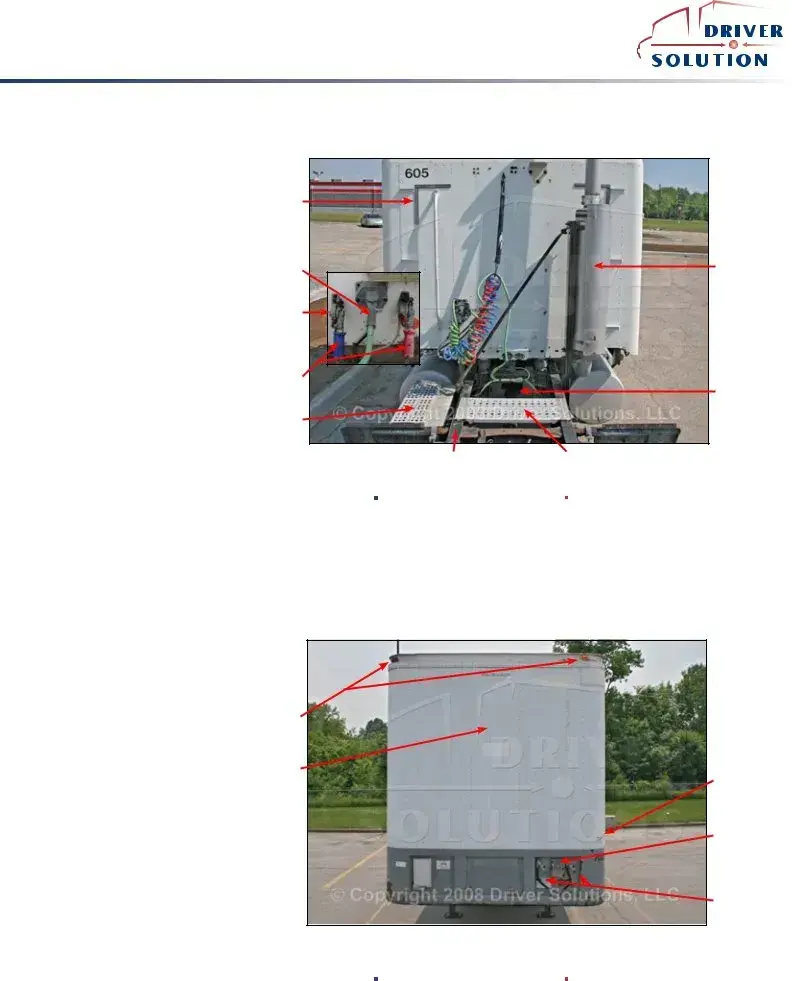

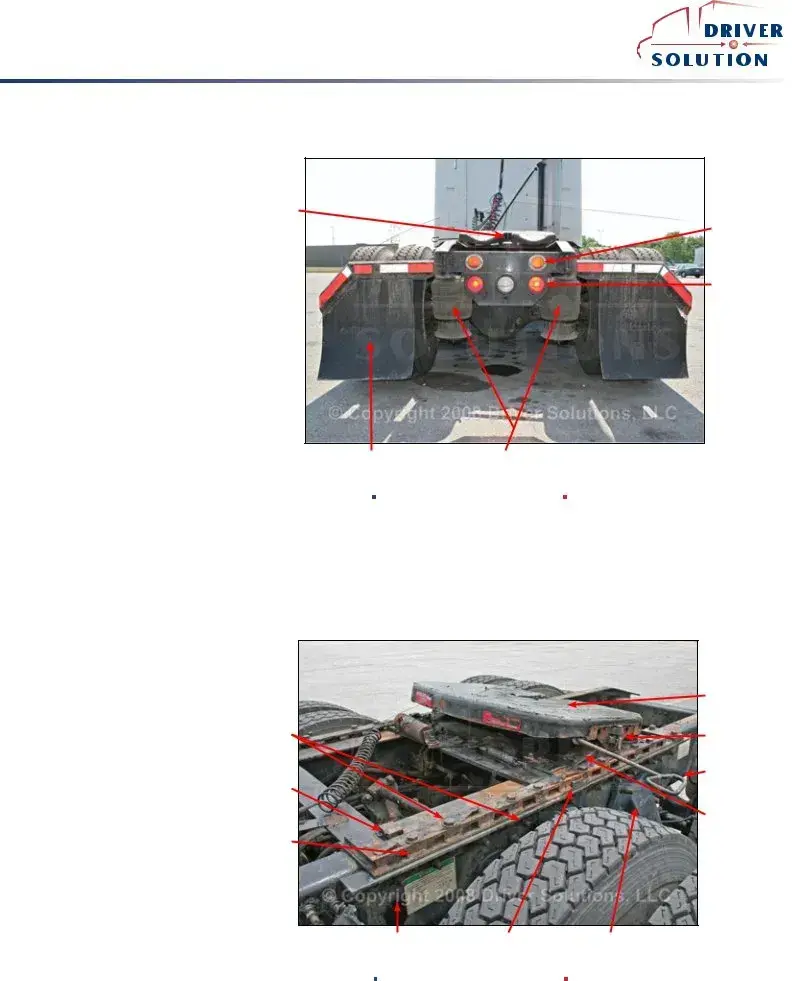

What items are typically included in the Pre Trip Inspection Checklist?

The checklist usually covers several key areas, such as the condition of the tires, brakes, lights, and windshield wipers. Other components may include checking fluid levels, ensuring that mirrors are properly adjusted, and inspecting the vehicle's overall integrity. Each item plays a critical role in ensuring that the vehicle operates safely and effectively.

How often should the Pre Trip Inspection be conducted?

The Pre Trip Inspection should be conducted before each trip. This practice ensures that the vehicle is in good working order on a consistent basis. Regular inspections help prevent breakdowns and accidents caused by mechanical failures.

What happens if a driver identifies an issue during the inspection?

If a driver identifies an issue during the Pre Trip Inspection, it is crucial to address it before proceeding. Depending on the severity of the issue, the driver may need to repair the problem or arrange for another vehicle. Ignoring issues can lead to unsafe driving conditions and potential legal consequences.

Is the Pre Trip Inspection Checklist form a legal requirement?

In many cases, yes. Federal and state regulations may require commercial drivers to complete a Pre Trip Inspection Checklist. Adhering to these regulations is important for maintaining compliance and ensuring safety on the road.

Can the Pre Trip Inspection Checklist be customized?

Organizations may choose to customize the Pre Trip Inspection Checklist to suit their specific needs or types of vehicles. Customization can include adding additional inspection items that reflect the unique risks or requirements associated with particular vehicles or operations.

How can individuals or companies access a Pre Trip Inspection Checklist?

A Pre Trip Inspection Checklist can often be obtained from various sources, including transportation regulatory agencies, industry associations, or safety organizations. Additionally, many online platforms offer templates and resources tailored to specific vehicle types and operating conditions.

What should be done with the completed Pre Trip Inspection Checklist?

After completing the Pre Trip Inspection Checklist, drivers should retain a copy for their records. If any issues were identified, documentation of the findings and corrective actions taken should also be kept. This practice not only helps in complying with regulations but also serves as a valuable record of vehicle maintenance and safety checks.

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®